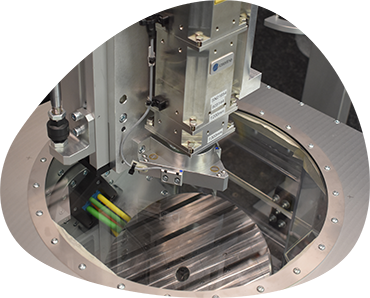

Laser polishing machine

3D POLISHING MACHINE SYLAS SLEEK 1000

Our 3D laser polishing machine SYLAS SLEEK 1000 is built on our 3D generic platform SYLAS SPARK and incorporates specific features corresponding to laser polishing needs.

LASER POLISHING PLATFORM

- The machine is designed to accommodate different lasers and optical systems needed to polish the various materials under our control.

- The machine can be configured for semi-automatic operation (manual loading/unloading of the parts to process) or fully automatic operation (in this case, the loading/unloading systems are adapted to the customer’s application needs).

- The software is designed so that the surface speed of the laser beam is kept constant regardless of the movements of each of the 5 axes of the machine.

- The machine is equipped with a position probe and automatic routines for the measure and registration of the actual parts position in space.

- The different optical heads on the machine are defined in the same way as the machining tools (milling tools, …) are identified on a conventional CNC. All the functions specific to laser polishing (avoidance trajectories, speed settings, …..) are automatically operated on the machine CAM software Top Solid’Cam 7. Therefore, the machine can be programmed in the same way as a state-of-the-art machine tool; a CNC programmer will find on an SYLAS machine an environment familiar to the best CNCs on the market.

Mechanical features

- Maximum dimensions of the processed parts: 200 × 200 × 200 mm.

- Maximum product weight: 14 Kg.

- Fully automatic offset setting process.

- Tool magazine.