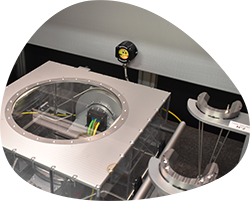

- The machine is designed to accommodate different lasers and optical systems.

- The machine can be configured for semi automatic or fully automatic operation.

- The software is designed so that the surface speed of the laser beam is kept constant regardless of the movements of each of the 5 axes of the machine.

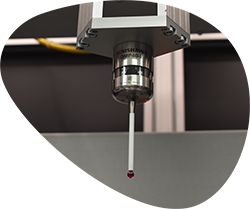

- The machine is equipped with a position probe and automatic routines for the measure and registration of the actual parts position in space.

- The machine is programmed in the same way as a modern machine tool. A programmer will therefore find on the SYLAS SLEEK 1000 machine an environment familiar to the best CNCs on the market.

Markets and applications

Our unique laser polishing process is applicable in different markets and can be adapted to many industrial applications.

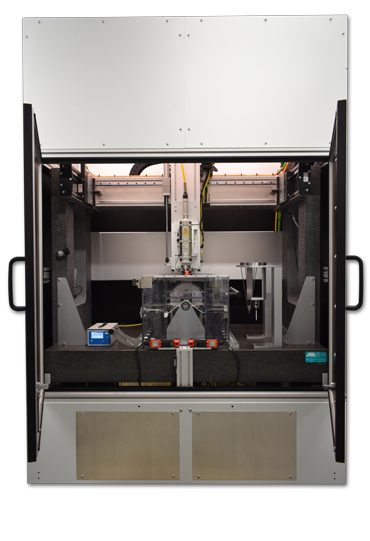

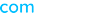

3D Polishing Machine SYLAS SLEEK 1000

Our 3D Laser polishing machine SYLAS SLEEK 1000 is built on our generic 3D platform SYLAS SPARK and incorporates specific features corresponding to the needs of laser polishing:

About SYLAS

SYLAS is a company resulting from a collaboration between the French company Optique and Microsystèmes and the Swiss company Unitechnologies. SYLAS has all of Unitechnologies’ know-how developed since 2012 in laser polishing. The SYLAS platform was developed in close collaboration with the company Optique et Microsystèmes

Contact us

+33 474 766 770

contact@sylas.com

7, Rue du Commerce 01460 PORT (France)