Laser Polishing Process

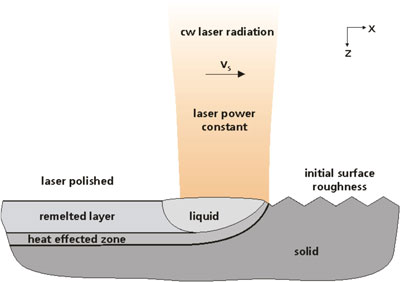

Laser polishing is based on the remelting of a thin material layer on the surface of the component to be polished. Thus, the material becomes fluid and smooth due to the physical properties of the surface tension. The obtained smoothing is then frozen during the almost immediate cooling of the material.

Polishing Parameters

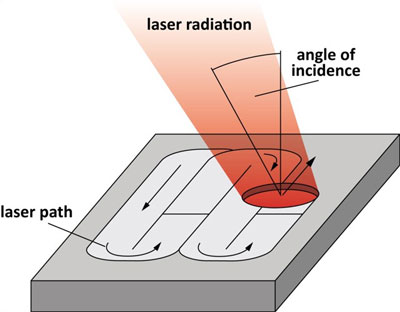

Depending of the material to be processed, the optimization of the polishing process requires the choice, respectively the monitoring of several parameters: laser beam diameter, speed, bath temperature, beam overlap between successive passes, instantaneous power delivered by the laser… In addition, the choice of the optical configuration and of incidence angles is also part of the correct selection of the laser polishing parameters.

Three-dimensional Polishing

Our solutions and systems offer the possibility to process any three-dimensional surfaces on sections whose geometry is freely programmable.